The Saturated Steam Process is the oldest method of in-container sterilization. Since air is considered an insulating medium, saturating the retort vessel with steam is a requirement of the process. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves. There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

Note on Terminology

In the Allpax retort control system there is terminology for an Uncleared Deviation or a (Cleared) Deviation condition that may exist. These terms are referred to in this paper. The definitions of these terms are as follows:

- CLEARED DEVIATION – When a deviation occurs, it may be possible to correct the process by adding time and/or temperature in order to compensate for the deviation. If this correction can take place in the retort, then the batch is declared to have a Cleared Deviation status. The Cleared Deviation status notifies the retort operator that a deviation was detected, but that corrective action was taken to compensate for the deviation (see Scheduled Process / Alternate Process definition). As in all cases, release of the product is subject to final review by the plant’s Quality Manager or Process Authority.

- UNCLEARED DEVIATION – When a deviation occurs in which an unsafe product condition exists and cannot be corrected for, then the batch is declared to have an Uncleared Deviation status. The Uncleared Deviation status notifies the retort operator that a deviation was detected and continues to exist in the batch.

Process Steps

Batch retorts execute a series of programmed process steps (also known as segments). These steps must be properly executed to achieve a sterilization process that meets the regulatory requirements imposed for food safety.

In a Saturated Steam process these steps are:

- Come Up Vent Open (A Sterilization Step)

- Come Up Vent Closed (A Sterilization Step)

- Cook (A Sterilization Step)

- Pressure Cool Fill

- Pressure Cool

- Atmospheric Cool

- Drain (Not Recipe-Configurable)

The following is a detailed description of each step:

COMEUP VENT OPEN – SATURATED STEAM

The purpose of this step is to saturate the vessel with steam, and to eliminate all air that may have been trapped in the retort. This step is accomplished by opening the vent valve and opening the steam control valve (and, if configured, opening the steam bypass valve.) An established vent time and temperature has been determined for the retort and product that is being processed. Since venting is both retort and product-specific, each product may have its own vent schedule, which will be incorporated into the product recipe. This information has been filed with the appropriate regulatory agency (FDA or USDA).

In order to successfully complete this phase, both time and temperature conditions established in the filed process must be met simultaneously. At the end of the scheduled vent time, the retort must be at, or above, vent temperature. If these conditions are not met, the vent time may be extended so that the vent temperature can be reached, without creating a deviation. Should the actual process be advanced to the next process step without satisfying both conditions simultaneously, then an Uncleared Deviation condition is created.

It is also imperative that the vent valve be open for the entire vent step. An open switch on the vent valve is provided for this positive indicator, as well as a vent closed switch. Should the vent open switch be seen as “not made,” or the “vent closed” switch be seen as “made,” or if both switches are seen as both “made,” at any time during the Vent Step, an Uncleared Deviation condition is created.

If water in the retort is detected at a level that is high enough to reach the bottom of the retort basket, an Uncleared Deviation condition is created.

COME UP VENT CLOSED – SATURATED STEAM

During this step, the vent valve is closed and the temperature is controlled and ramped to Cook Temperature (unless multiple Come Up Vent Closed steps are utilized.) In order to successfully complete this phase, both time and temperature conditions, established in the recipe must be met simultaneously. At the end of the scheduled come-up time, the retort must be at, or above, scheduled cook temperature. If it does not meet these conditions, the step time may be extended so that the recipe temperature can be reached, without creating a deviation. Should the actual process be advanced to the next phase without satisfying both conditions simultaneously, then an Uncleared Deviation condition is created.

If water in the retort is detected at a level that is high enough to reach the bottom of the retort basket, an Uncleared Deviation condition is created.

Should the actual process be advanced to the next phase without satisfying all conditions simultaneously, then an Uncleared Deviation condition is created.

COOK / HOLD / STERILIZATION – SATURATED STEAM

The purpose of the Cook Step is to maintain the recipe temperature for the time required by the recipe. In order to successfully complete this step, the temperature condition established in the recipe (the filed process) must be met for the length of time defined for the step. Should a temperature drop occur at any time during the step, then a temperature deviation condition is created. Should an alternate process be available when a temperature deviation occurs, then the batch is labeled as a Cleared Deviation. Should the alternate process(es) not be successfully administered, then the Uncleared Deviation condition for the batch is created.

During this step, the operator is required to make operator entries: at least one check and entry of the MIG reading entry, one for the Chart reading, and one for the Bleeder Valve check. All operator entries must be made for the step to be completed.

During the Cook Step of a saturated steam process, the batch may be declared a Temperature Deviation or an Uncleared Deviation after the MIG / RTD comparison check is made.

During the Cook Step of a saturated steam process, the batch would be declared an Uncleared Deviation if the operator made an entry that indicated a bleeder valve failure after making a visual check.

During the Cook Step of a saturated steam process, the batch would be declared an Uncleared Deviation if water is detected at a height sufficient to reach the bottom of the basket.

PRESSURE COOL FILL – SATURATED STEAM

This step begins the cooling process. The cooling water enters the retort as overriding pressure control is initiated. In the initial phase of this step, steam is collapsed by the cooling water, which is displaced by large quantities of air. As the vessel fills, pressure will build as the air is compressed by the rising water level. The BPR valve is used to relieve excess pressure while the air valve is used to make up pressure.

When the water level, defined in the recipe, is reached (normally at the top of the basket), the step ends.

PRESSURE COOL – SATURATED STEAM

This step continues the retort cooling process. Cooling water continues to flow into the Process Vessel and flows out through the drain valve, which controls the level. Control to the recipe pressure setpoint is maintained using the Pressure Relief valve and Air (Pressure Makeup) valve with a dead-band of .5 to 1.0 psi. When the pressure cool time is completed and the recipe temperature is met, the step ends.

ATMOSPHERIC COOL – SATURATED STEAM

This step continues the retort cooling process. Cooling water continues to flow into the Process Vessel and flows out through the drain valve, which controls the level. Control is removed from the Pressure Relief valve, releasing pressure by opening the vent valve (note: pressure may be steadily released using ramp control employed in a second Pressure Cool step). When the atmospheric cool time is completed, and an established temperature setpoint in the Process Vessel is achieved, the step ends.

DRAIN – SATURATED STEAM

This step drains the water from the retort. The drain is opened the water gravity-drains from the retort. When the level condition is met, the step ends. Note: To accelerate the drain step, limited overriding air pressure (2-5psi) may be used during the step.

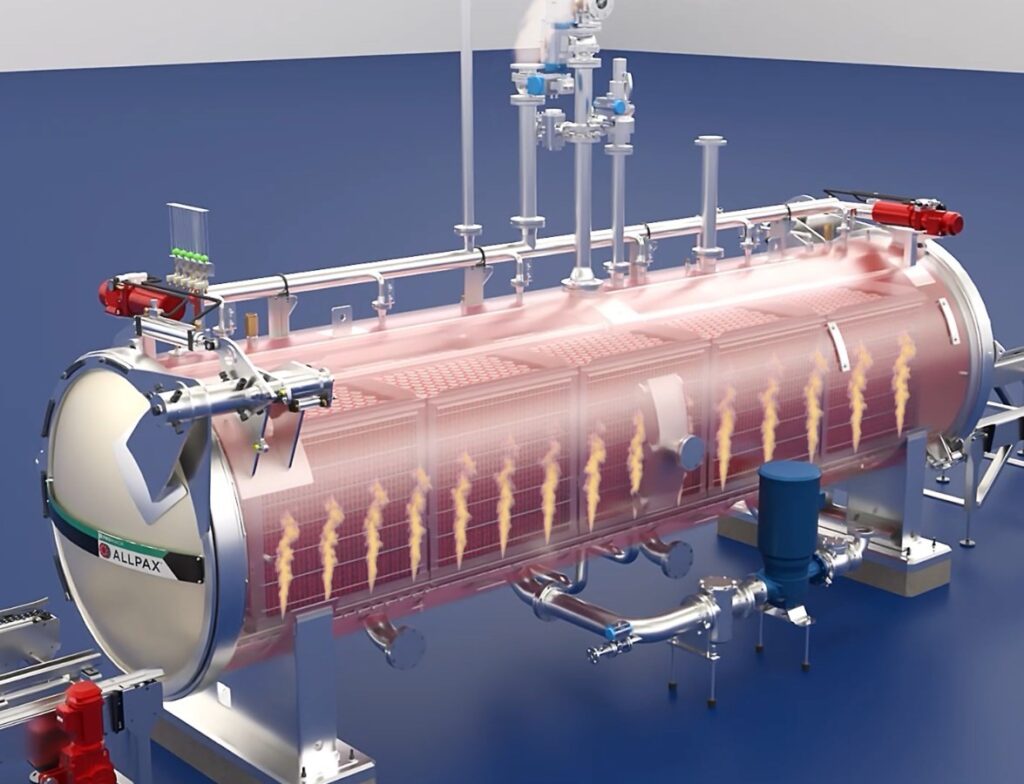

Click the above image to view an animation of the saturated steam process

A complete line of retort room equipment, including horizontal saturated steam retorts. See Allpax Steam Retorts.