The word “retort” can mean two drastically different things. First, it can be a reply to an argument or charge, usually quick, witty, and/or cutting. It can also refer to a vessel or chamber in which substances are distilled or decomposed by heat. Since Allpax is in the food sterilization business, it should be clear that we will talk exclusively about the latter.

Beyond this simplified definition, what really is a retort? What does a retort do? What can a retort be used for? As a leading authority, we are here to answer any questions about retorts and the food sterilization process.

What is a Retort?

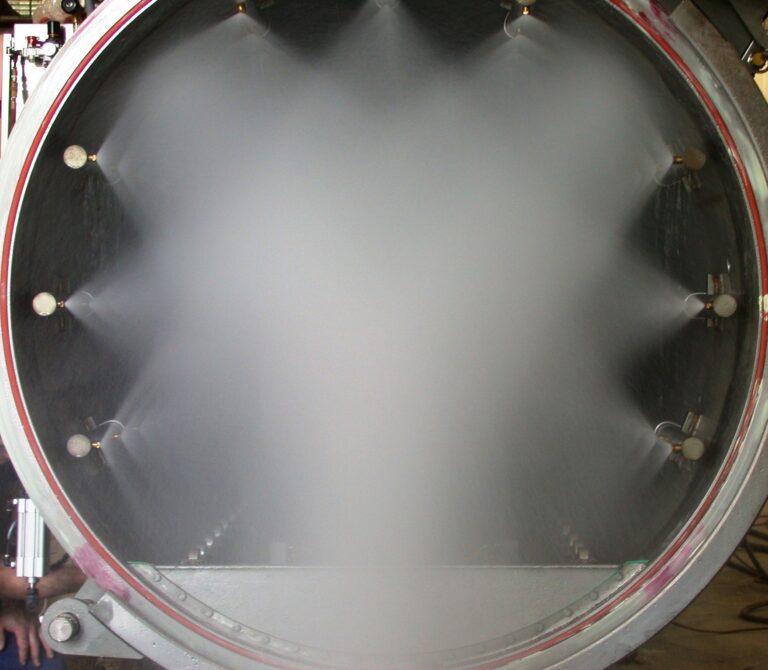

A retort (also autoclave or sterilizer) is a pressure vessel used in the food manufacturing industry to commercially sterilize food. This process is performed after the product has been placed into a container and hermetically sealed.

The method of sterilization is a thermal-based process. The application of high heat to the product preserves nutrition and appearance, while also extending shelf-life. The high temperatures destroy pathogenic organisms that may be in the container or food product.

Thermal processing of shelf stable, low-acid foods is performed at temperatures at or above 250°F (121°C) to 275°F (135°C). The higher the temperature, the shorter the time the product needs to be exposed to heat.

What products can be sterilized in a retort?

In the food manufacturing industry, commercial sterilization is used for foods intended for a longer shelf life. These shelf stable, low-acid foods come in a variety of different containers that are then hermetically sealed, including:

- Metal canned goods

- Glass bottles

- Plastic and other flexible pouches

- Rigid and semi-rigid trays

- Vacuum-packaged foods

- Other common rigid and flexible packaging

Shelf stable, low-acid foods are defined as products with a finished equilibrium pH greater than 4.6 and a water activity greater than 0.85. Examples of this category of food are:

- Meats and seafood

- Fruits and vegetables

- Beans and legumes

- Soups, sauces, and condiments

- Ready-to-eat meals

- Dairy products, including yogurt

- Pet food

- Baby food

- Dehydrated foods

- Ready-to-drink (RTD) beverages, including soy milk and plant-based protein drinks

How does retort sterilization work?

The sterilization process involves four critical phases that ensure complete microbial elimination:

Heat penetration:

- Add an appropriate amount of water into the retort

- Directly heat it with steam

- Quickly raise the temperature to the required sterilization temperature (around 121°C).

This high-temperature steam penetrates packaging materials to reach all food surfaces. At the same time, the pressure is adjusted to a predetermined level through the pressure valve and exhaust valve.

Sterilization:

The steam directly enters the sterilization autoclave for heating, while circulation ensures that the product is heated evenly. Cellular structures of bacteria, molds, and spores are completely destroyed. Sterilization time varies from about 15 minutes to several hours depending on different food types and packaging materials. Multiple cycles of sterilization can be required for adequate sterilization.

Cooling:

After sterilization, the process enters the cooling stage. To quickly and effectively reduce the temperature of the food, the product is usually cooled twice. The supply of steam in the retort is stopped, and cooling water is introduced into the machine for cooling. The cooling phase ends until the product has cooled down to the desired temperature.

Quality Control & Unloading:

Precise control maintains nutritional content and sensory properties, while pressure control prevents package deformation during processing. After processing, the packaged food is safely removed from the sterilizer, transferred to a new area to await packaging.

What is the difference between batch retorting, continuous retorting, and aseptic processing?

Understanding the pros and cons of batch retorting versus continuous and aseptic sterilization helps organizations make an informed purchasing decision. So, what is the actual difference between the different processes?

Batch retorting

Sterilizes a full, sealed load of product within containers, like cans or pouches, in an autoclave. The product is heated to commercial sterility, and the entire batch is then cooled down before being removed.

Continuous retorting

A high-volume, automated process where containers are continuously fed into the retort and then continuously discharged.

Aseptic sterilization

The product is sterilized separately using high-heat treatment, then rapidly cooled. It is filled into pre-sterilized containers in a sterile environment and then sealed without further processing.

Factors to consider in your selection process include:

- Product type

- Package type

- Product/package/process flexibility needs

- Throughput requirements

- Product life cycle

- Price point of the product

- Time to market requirements

- Size of the overall investment both upfront and down the road

What batch retorts configurations are available?

Batch retorts are available in several configurations. First, they can be static or agitating style machines.

- A static retort is typically used for conductive (i.e.: viscous) heating products where the product does not benefit from any kind of movement during the process (heat or cooling).

- Agitating style retorts are typically used for convective (i.e.: “flowable liquid”) type products such as dressings and sauces that benefit from some product movement (i.e.: ‘stirring”) in the container during the process. This movement can be from:

- A process stand-point, to improve the rate of heat transfer into/out of the container

- Or, from a product quality stand-point to ensure taste, appearance, or nutritional value

Agitating style machines can utilize various methods of agitation depending on the orientation of the product container.

- Vertically oriented containers, such as cans or glass/plastic bottles, are typically agitated in a rotary fashion, either axially or end-over-end.

- With horizontally oriented containers, such as flexible pouches and semi-rigid bowls and/or trays, the preferred method is horizontal reciprocation. Allpax’s Gentle Motion® and SHAKA® are two forms of such agitation.

What are some batch retorts process delivery methods?

Batch retorts can employ various methods of process delivery. Some of which utilize overpressure (also known as counter-pressure) to help protect the integrity of the container during the process. For example, to keep the package from bursting as temperature and pressure build inside the container during the process.

Rigid containers, such as steel cans, are able to withstand large differences between the pressure inside and outside of the container. Therefore, these types of containers typically do not require overpressure. They can be processed in a 100% saturated steam environment without the use of overpressure during the heating phases.

On the other hand, more fragile flexible and semi-rigid containers cannot withstand high pressure differentials. For these products, air is introduced into the autoclave to provide overpressure, which maintains package integrity during the process.

These types of containers require more sophisticated overpressure process delivery methods such as:

Because air is an insulator, stirring or mixing the process media in the retort is needed to avoid cold spots. This ensures even temperature distribution throughout the machine and product load. This mixing is accomplished by:

- the different water flow methodologies mentioned above

- or via a fan in the case of steam-air retorts

- and/or via mechanical rotation of the insert/drum for agitating style machines

Why is overpressure so important?

Overpressure is critical during the cooling phases of a sterilization process. Precise control of overpressure during the initial phases of cooling is important to avoid two critical production issues:

Buckling

As cooling water is introduced into the retort, it collapses the steam created in the heating step(s). Without introduction of air overpressure during cooling, the pressure in the retort can suddenly drop due to steam collapse, creating a vacuum. When this happens, the pressure differential between the outside and inside of the container becomes too great, causing the container to burst. This is known as buckling.

Paneling

Likewise, ramping the pressure down in the latter stages of cooling prevents crushing the container as the temperature and pressure inside the container subsides. This is known as paneling.

Additionally, while the sterilization process inactivates or destroys bacterial pathogens, it does not destroy all microscopic spoilage organisms. Thermophiles are bacteria that can withstand temperatures well above typical retort temperatures. For this reason, the product must be cooled down to a temperature below which these organisms reproduce, thus causing thermophilic spoilage.

If you have any questions about autoclaves, retort equipment, and/or commercial sterilization, please visit www.Allpax.com, email info@allpax.com, or call us directly (985) 893-9277.